Label Feeder Juki

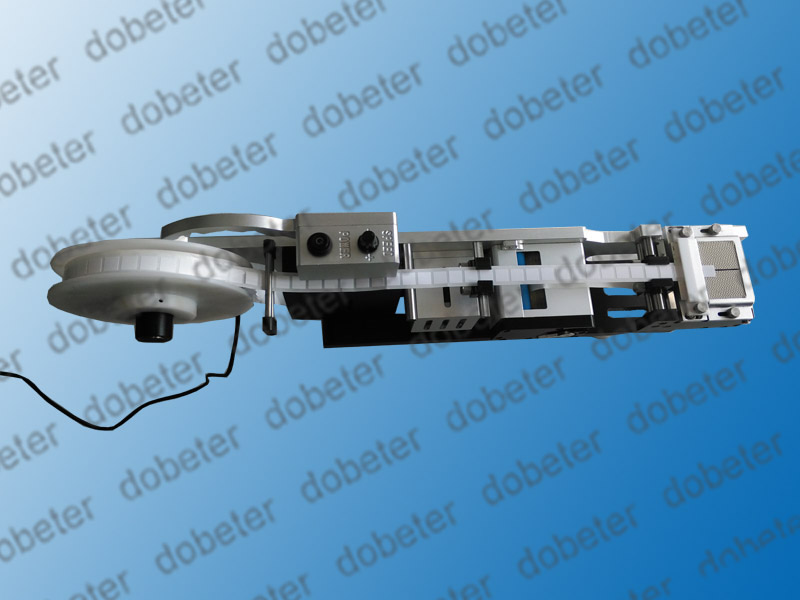

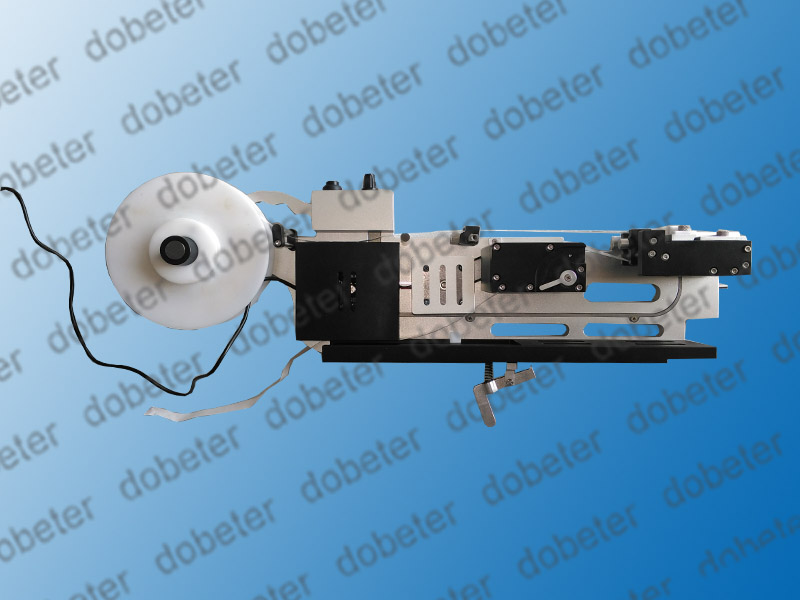

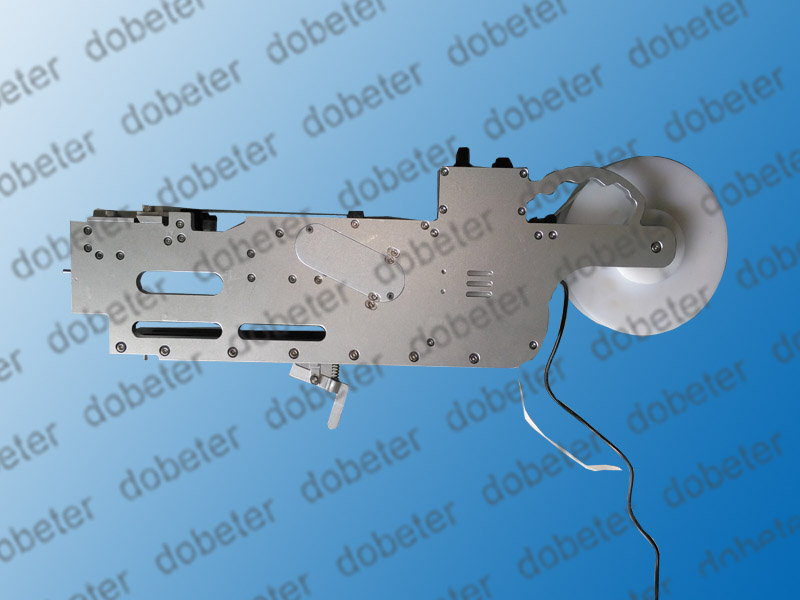

Our Label Feeder Juki can use your existing Juki SMT pick and placement equipments to place labels, such as Juki SMT pick and palce machines such as KE710, KE720, KE730, KE750,KE760,KE2000/2010/2020/2030/2040/2050/2060/2070/2080/3010/3020/1070/1080 FX-1/ FX-2/FX-3 and so on.

Our Label Feeder Juki approach is faster and more accurate than hand placement: Labels are placed at the normal machine rate and as accurately as normal components. The result is a far more cost effective solution to board marking. Also maintenance costs is very low.

An in-line label applicators is very expensive and requires additional floor space, Laser marking is another option and while this does facilitate realtime data marking it comes with compounded cost penalties and is not suitable for all applications. Our Juki Label Feeder fits easily onto existing placement machines and presents the labels to the pick-and-place machine as if they were just another component, what you need to do is just to add a vision file for the label as a leadless chip component and your work is done! No special programming or training is required. So our Label Feeder Juki approach can save time , money and floor space.

Label Feeder Juki

Applied to : those Juki SMT machines KE710, KE720, KE730, KE750,KE760,KE2000/2010/2020/2030/2040/2050/2060/2070/2080/3010/3020/1070/1080 FX-1/ FX-2/FX-3 such as Juki, Juki X, Juki XII and so on.

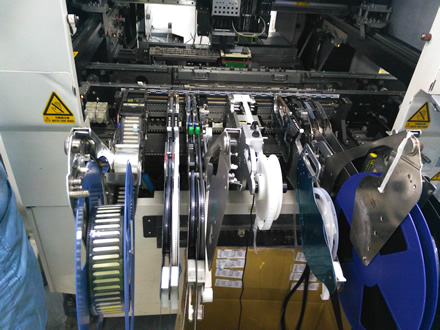

label feeder Juki into Juki SMT machine:

We have three kinds of Liner(web) width for label feeder Juki : 50mm, 85mm and 100mm, also we can make customized liner width as your request, our label feeder can peel and present more than 2 lables at one time, so it is more efficient and productive.

Specs :

| Specification | Minimum | Maximum |

| Media Size | 2 mm x 2 mm | 31 mm to customized one * 50 mm, 31 mm to customized one * 85mm , 31 mm to customized one * 100mm |

| Media Thickness | 0.05 | 1 |

| Liner Width | 1 | 50mm 85mm 100mm customized one |

| Liner Thickness | 0.05 | 1 |

| Feed Rate | 0 mm / sec | 95 mm / sec |

Labels or other adhesive backed media :

Our Label Feeder Juki is extremely versatile, it can also be adapted to present a wide assortment of adhesive backed products : distance pads, shields, thermal conduction pads, Kapton dots, special masks, metal sheets with thickness more than 1mm or similar special parts. In one row applied onto a liner it is possible to feed these parts automatically in the pick and place system with a label feeder. In one row more than 2 labels can be feed thus our Label Feeder Juki is more efficient.

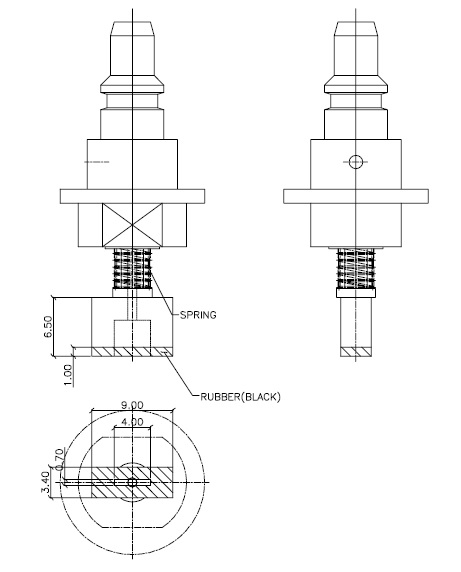

Customized Nozzles For Label Feeder

We also supply you cutomized nozzles for label feeder juki , send us your datasheet of labels or samples we can design and manufacture the special nozzles for you :